In Germany there are many sewage treatment plants, built in the 70s or 80s and now have to be overhauled and expanded due to their poor structural condition, increased population and outdated technology. Often there also is the fact that either required discharge values can no longer be adhered to, or pollution of the waste water has changed or the process no longer runs properly, which makes necessary a further treatment stage and chemical precipitation.

While the municipality has decided to renovate and collects cost comparisons for different process variants, these at small sewage treatment plants <5000 PE are often compared to the alternative of connecting the plant to the larger sewage treatment plant located next to it by means of a pressure pipe. The process variants examined are mostly limited to conventional aeration tanks with sludge stabilization and membrane aeration systems that are placed in the existing renovated or in new tanks. All variants incur high costs for the construction work, new technology and installation, which is why the municipalities almost always decide in favor of the pressure pipeline.

Unfortunately, the “compact system” variant is often ignored in studies and cost comparisons. If one were to include compact systems in the study, the connection line to a larger system would only be preferred under certain circumstances, e.g. if the connection system is very close, the gradient in the pipeline does not require any further pumping manholes and therefore the construction of the pressure pipeline does not involve high investments and additional land.

.

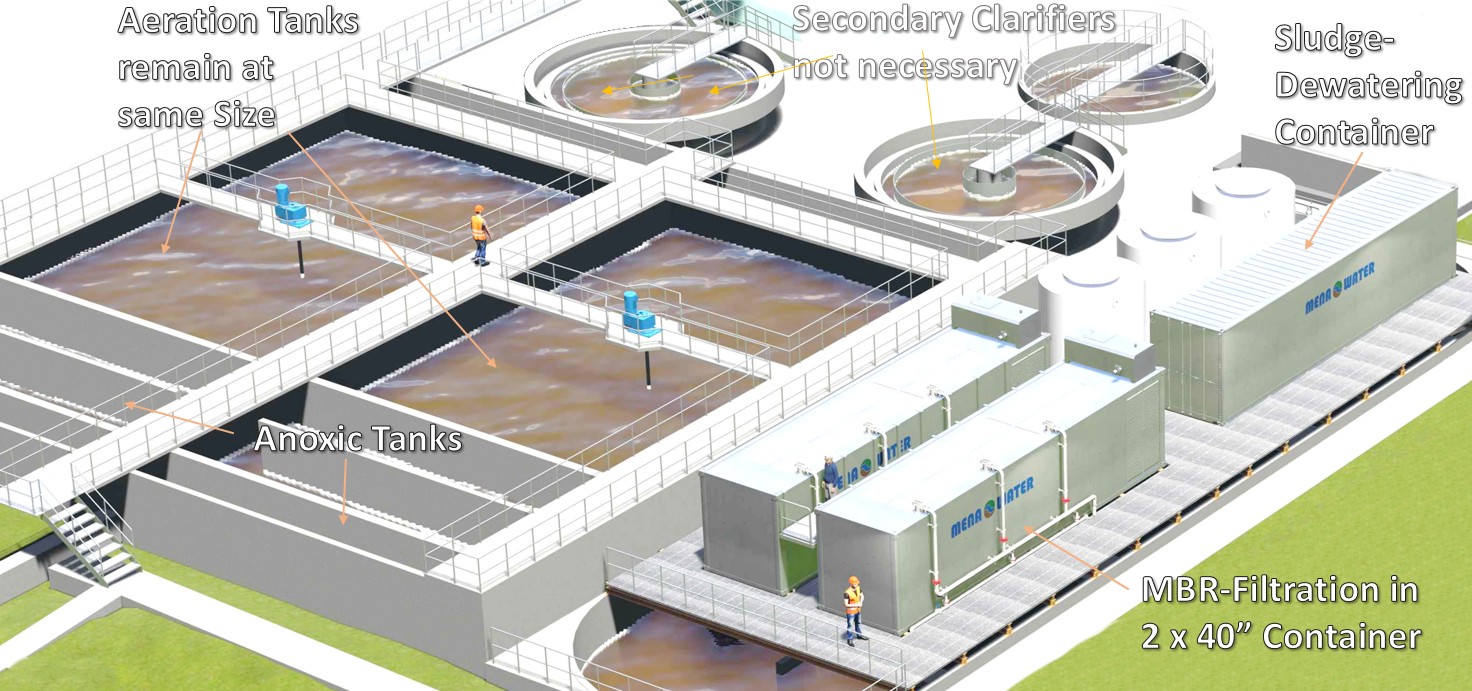

Sample: Upgrade of conventional Sewage Treatment Plant with flow of 400 m³/day to 2000 m³/day using 2 x 40” MBR-Container, placed on Buffertank. Sludge Dewatering in Container behind.

…

An MBR (Membrane Biological Reactor) compact system is a cost-effective variant. The complete membrane filtration unit including pumps, ventilation, control and sensor technology is pre-installed in a container (see Figure down). The MBR container is placed as a “plug & play” unit next to the existing aeration tank (see Sample) and fed from there by means of circulation pumps. The MBR system does not require any secondary clarifiers and no further treatment. Since the entire control and machine technology is arranged inside the compact housing, it can be implemented quickly, combined with easy operation and maintenance. The factors mentioned result in reduced construction, installation and operating costs. As an option, it is possible to facilitate operation by means of remote monitoring, minimize maintenance costs and further reduce operating costs.

Since the biology in the case of membrane filtration can be operated with a much higher concentration of activated sludge compared to the conventional process, the existing activated sludge tank can be charged with up to four times more wastewater.

This means that if a conventional system is overtaken by an MBR compact system, with the same space requirement and significantly improved drainage values, an expansion of up to four times, and in some circumstances even more (see a case study in Figure). The treated wastewater is bacteria-free and almost virus-free and has a very low phosphate content, so it can safely be discharged into receiving waters to sensitive catchment areas (swimming lakes, water sports, tourism) and it corresponds to EU bathing water quality.

Some of the many advantages of MBR Package Plants over conventional wastewater treatment are summarized below:

- Treatment of higher amounts of wastewater with small foot print

- Improved drainage values, which in conventional systems can otherwise only be achieved with more extensive treatment and additional chemicals

- Microplastics, bacteria and viruses are removed, a key issue in the future

- Biological phosphate removal ≤0.1mg P / l without precipitants, which lowers the operating costs (precipitants)

- the purified water can e.g. can be used directly as irrigation water with bathing water quality or as industrial service water and also discharged into bathing water

- The purified water can be used decentrally and is not lost to the location, as in the case of a pressure pipe

- the compact system is fully automatic and can be monitored remotely, which improves process control and saves operating personnel

- Easy installation, pre-installed “Plug & Play” system, which greatly reduces the on-site installation costs

- closed system, no odor and noise emissions

- Also optically clean solution

- Can be expanded as required in the future due to the modular design

MENA-Water produces complete MBR compact systems, finished as standard sizes. This enables us to guarantee easy handling and transport, rapid availability and a smooth installation and commissioning process. The systems are not designed as a temporary solution, but made of stainless steel and equipped with quality equipment (redundant), which guarantees a long service life and functionality.

The package system includes all main components in a compact housing:

- Stainless steel tanks V2A / V4A

- Complete piping including scouring air system

- Blowers and ventilation elements for aeration and membrane cleaning

- Recirculation pumps, permeate pump, backwash and chlorine dosing system

- Process control with PLC, online measurement technology and modem for remote web monitoring

For further information and inquiries, please contact:

Mena Water FZC

info@mena-water.com

www.mena-water.com

This post is also available in deutsch.